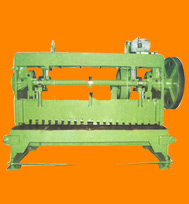

Press Brake

A press brake, also known as a brake press, is a machine tool for bending sheet and plate material, most commonly sheet metal. It forms predetermined bends by clamping the work piece between a matching punch and die.

Typically, two C-frames form the sides of the press brake, connected to a table at the bottom and on a moveable beam at the top. The bottom tool is mounted on the table with the top tool mounted on the upper beam.

A brake can be described by basic parameters, such as the force or tonnage and the working length. Additional parameters include the amplitude or stroke, the distance between the frame uprights or side housings, distance to the back gauge, and work height. The upper beam usually operates at a speed ranging from 1 to 15 mm/s.

There are several types of brakes as described by the means of applying force: mechanical, hydraulic.

In a Mechanical press, energy is added to a flywheel with an electric motor. A clutch engages the flywheel to power a crank mechanism that moves the ram vertically. Accuracy and speed are two advantages of the mechanical press.

Hydraulic presses operate by means of two synchronized hydraulic cylinders on the C-frames moving the upper beam. Hydraulic brakes produce accurate high quality products are reliable, use little energy and are safer because, unlike flywheel-driven presses, the motion of the ram can be easily stopped at any time in response to a safety device.