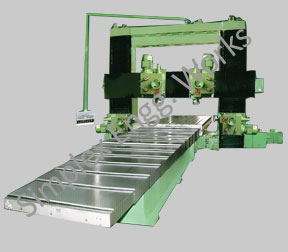

Planner Machine

A planer, Plano miller is a type of metalworking machine tool that uses linear relative motion between the work piece and a single-point cutting tool to machine a linear tool path. Its cut is analogous to that of a lathe, except that it is (archetypally) linear instead of helical. (Adding axes of motion can yield helical tool paths) A planer is analogous to a shaper, but larger, and with the entire work piece moving on a table beneath the cutter, instead of the cutter riding a ram that moves above a stationary work piece. The table is moved back and forth on the bed beneath the cutting head either by mechanical means, such as a rack and pinion drive or a lead screw.

The most common applications of planers and shapers are linear-tool path ones, such as:

Generating accurate flat surfaces. (While not as precise as grinding, a planer can remove a tremendous amount of material in one pass with high accuracy.)

Cutting slots (such as keyways).

|

Plano Milling Machine is widely used in industries for precise shaping of metals & various solid materials. These entire machines are ideal for various processes such as slot cutting, routing, welding & turning in metallurgy industry. We make the range of machines available to the clients in various configurations as per their application requirements.

|

Ask for Price |

| Technical

Specifications |

| Model No. |

SPM-120 |

SPM-150 |

SPM-180 |

SPM-210 |

SPM-250 |

SPM-300 |

| Length of Stroke |

1800 to 15000 as per

Order/requirement |

| Width between Columns |

1200 |

1500 |

1800 |

2100 |

2500 |

3000 |

| Height under Cross Rail |

1200 |

1500 |

1500 |

1500 |

1500 |

1500 |

| Face of Cross Rail |

450 |

450 |

550 |

600 |

650 |

700 |

| Face of Columns |

325 |

325 |

450 |

500 |

500 |

500 |

| Width of Table |

875 |

1050 |

1200 |

1400 |

1500 |

1800 |

| No. of Table Feeds |

Stepless Infinitely Variable

Speeds with AC Variable Frequency Drive |

| Table Feed for Milling per Minute |

40 to 200 |

| Table Repaid feed per minute |

600 |

|

Standard

Accessories

- One Milling Head on Cross Saddle

- Table Feed Drive Gear Box

- Cross Feed Drive Gear Box

- Lifting Drive Motor

- Electrical Control Panel

|

Optional

Accessories

- Extra Milling Head on Cross Saddle

- Extra Milling Head on Side Column

- Lifting Drive Gear Box for Side Milling Head

|

|

|

|

|

|