The

Plate Rolling Machines, Bending machine widely used for bending and rolling metal sheets into tubes of different diameters. Our plate rolling machine has modifiable rolls, therefore reducing the running time and improving the output. These rolling machines are compatible with both steel fabrication and aluminum, amid high level of constant precision.

We offer both mechanical and hydraulic plate rolling machines that are manufactured with accuracy, high speed productivity, adjustable top roll and fixed bottom rolls.

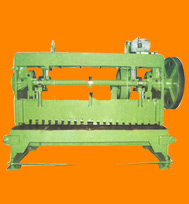

Our range of Shearing Machines :

- Mechanical Plate Rolling

- Hydraulic Plate Rolling