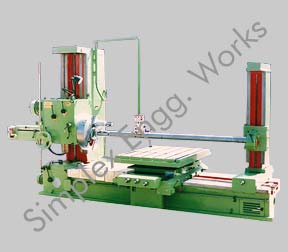

Boring Machine

A horizontal boring machine or horizontal boring mill is a machine tool which bores holes in a horizontal direction. There are two main types — Table and Floor. The table type is the most common and, as it is the most versatile, it is also known as the universal type.

A horizontal boring machine has its work spindle parallel to the ground and work table. Typically there are 3 linear axes in which the tool head and part move. Convention dictates that the main axis that drives the part towards the work spindle is the Z axis, with a cross-traversing X axis and a vertically traversing Y axis. The work spindle is referred to as the W axis and, if a rotary table is incorporated, its centre line is the C axis.

Horizontal boring machines are often heavy – duty industrial machines used for roughing out large components but there are high-precision models too.

In machining, boring is the process of enlarging a hole that has already been drilled (or cast), by means of a single-point cutting tool, Boring is used to achieve greater accuracy of the diameter of a hole, and can be used to cut a tapered hole. Boring can be viewed as the internal-diameter counterpart to turning, which cuts external diameters.

There are various types of boring. The boring bar may be supported on both ends (which only works if the existing hole is a through hole), or it may be supported at one end (which works for both through holes).

|

| Horizontal

Boring Machine |

Horizontal Boring machine manufactured by us are extensively used in industries for various applications. These boring machines have provision of inching feeds of gearbox and spindle speeds. The assortment of machines offered by us ensures excellent durability and requires low maintenance. Rigid in construction, these entire boring machines ensure excellent performance while bearing all the working stresses.

FEATURES

- The Verniers Casting is Done with the Mixture of 25% Steel and Ferro Chrome. To Acquire Proper Brinell Hardness. The Machine is Manufactured to Grade-1 Limit of Accuracy.

- Heavily Ribbed Box Type Bed and Sturdy Box Type Columns to Withstand the Heavy Cutting Force even at Elevated Heights.

- High Accuracy of Machining due to Accurately Grounded Reliable Ways of Bed and Pillars and Fine Positioning by Dial Gauge and Vernier Digital Readout System.

- Longitudinal and Cross Table Traverses, Vertical Travel of Head Stock and Boring Supports are Provided with Rapid Movements as well as feeds.

- Provision of Inching Spindle Speeds and Feeds of Gear Box.

- Precise Synchronized Vertical Travel of Headstock and Boring Stay Support.

- Special Arrangement: To Set Rotary Table Perfectly at Right Angle.

- Safety Clutches: Facing Mechanism, Sliding Mechanism, of Cross Slide, Rotary Movement of Work Table and Working Spindle Longitudinal Movement.

- Apart from Above Safety Measures, Suitable Shear Pins are also provided for the Total Safety of Machine.

- Adjustable Stoppers to Trip Longitudinal and Vertical Feeds at Desire Points are also provided.

- Hand Operated Knurled Socket Attached to Headstock Drive Motor and Operated Wheel Attached to Feed Gear Box.

- Motor for the Safe Engagement of Speeds and Feeds Respectively.

- Mechanical Clamping of All Axes.

- Manual Boring Head Height Setting Adjustment with a Lever Attached to Feed Gear Box.

- Conveniently Arranged and Simple Control Panel System Ensure Easy Operation.

|

Ask for Price |

| Technical Specifications |

| Model No |

NHB80 |

NHB100 |

NHB110 |

NHB125 |

NHB130 |

NHB 150 |

| Alloy Steel Work Spindle Hardened & Ground-Diameter

|

80 |

100 |

110 |

125 |

130 |

150 |

| Morse Taper Number |

5 |

6 |

6 |

6 |

6 |

6 |

| Max. Longitudinal Movements of Working Spindle |

510 |

510 |

510 |

600 |

600 |

650 |

| Number of Spindle Speeds |

9 |

9 |

9 |

9 |

9 |

9 |

| Range of Spindle Speeds – R.P.M. |

15 to 300 |

15 to 250 |

15 to 250 |

15 to 250 |

15 to 250 |

12 to 250 |

| Longitudinal Work Spindle Feeds Nos. |

9 |

9 |

9 |

9 |

9 |

9 |

| Max. Height of the Spindle Axis from Table Surface |

925 |

1000 |

1100 |

1200 |

1300 |

1500 |

| Min. Height of the Spindle Axis from Table Surface |

25 |

30 |

30 |

30 |

30 |

30 |

| Dimensions of the Rotary Table |

900*1105 |

1030*1375 |

1100*1450 |

1220*1675 |

1320*1775 |

1500*2000 |

| Longitudinal table Traverse |

1625 |

1775 |

1925 |

2050 |

2800 |

2950 |

| Long. Table Traverse Feeds (Including one Rapid) |

10 |

10 |

10 |

10 |

10 |

10 |

| Transversal Table Travel Feeds (Including one Rapid)

|

10 |

10 |

10 |

10 |

10 |

10 |

| Vertical Head Stock Travel Feeds (Including one Rapid) |

4 |

4 |

4 |

10 |

10 |

10 |

| Rotary Table Automatic Feeds (Including one Rapid) |

10 |

10 |

10 |

10 |

10 |

10 |

| Max. Cross Movement of the Table |

1000 |

1100 |

1300 |

1500 |

2000 |

2000 |

| Max. Distance between Stay Bearing & Facing Head |

2400 |

2690 |

2800 |

2950 |

3600 |

3950 |

| Facing Head Diameter |

505 |

555 |

600 |

650 |

650 |

700 |

| Weight Approx. in Kgs. |

8500 |

9500 |

11000 |

16000 |

17000 |

19000 |

|

Our manufactured range of Vertical Boring Machine is ideal for machining various components in diverse industries. All these boring machines offer advanced design features and rugged removal capacity for high precision machining. The range of machine is highly acclaimed by the clients for their attributes like durability, longer service life and high tensile strength. For the convenience of the clients, we modify and configure these machines as per their specifications.

|

Ask for Price |

| Technical Data of Vertical

Turning Cum Boring Machine |

| S. No. |

Model No. |

VT-1 |

VT-1.5 |

VT-2 |

VT-2.5 |

VT-3 |

VT-4 |

VT-5 |

| 1 |

Max. Turning Dia |

1100 |

1700 |

2200 |

2700 |

3200 |

4200 |

5200 |

| 2 |

Table Dia |

1000 |

1500 |

2000 |

2500 |

3000 |

4000 |

4500 |

| 3 |

Max. Working Height |

600 |

1500 |

1500 |

1500 |

1600 |

1600 |

1600 |

| 4 |

Max. Vertical Travel of Ram Head |

500 |

800 |

800 |

800 |

900 |

900 |

900 |

| 5 |

Swivel Angle of Ram Head |

±30 |

±30 |

±30 |

±30 |

±30 |

±30 |

±30 |

| 6 |

Horizontal Travel of Side Ram Head (Optional) |

250 |

375 |

500 |

625 |

750 |

900 |

1000 |

| 7 |

Vertical Travel of Side Ram Head (Optional) |

400 |

1300 |

1300 |

1300 |

1400 |

1400 |

1400 |

| 8 |

No. of Table Speed |

STEPLESS INFINITELY VARIABLE SPEEDS WITH AC

VARIABLE FREQUENCY DRIVE |

| 9 |

Range of Table Speed RPM |

6-60 |

4-40 |

3-30 |

2-20 |

1.5-15 |

1-10 |

0.7-7 |

| 10 |

No. of Feeds Vertical / Horizontal |

6-60 |

6 |

6 |

6 |

6 |

6 |

6 |

| 11 |

Range of Feed Vert/Hor (mm/min) |

3-12 |

2-8 |

1.5-6 |

0.5-5 |

0.5-5 |

0.5-5 |

0.5-5 |

| 12 |

Rapid Traverse of Head (mm/min) |

300 |

300 |

300 |

250 |

250 |

250 |

250 |

| 13 |

Main Motor (H.P.) |

7.5 |

15 |

20 |

25 |

30 |

40 |

50 |

| 14 |

Ram Feed Gear Box Motor (H.P.) |

3 |

3 |

5 |

5 |

7.5 |

7.5 |

7.5 |

| 15 |

Auto Lifting of Cross Rail Motor (HP) |

3 |

3 |

5 |

5 |

5 |

5 |

5 |

|

* Specification of bigger sizes can supplied on request.

Note: Since the results of most modern research and development are

being constantly applied to our machines, illustrations, construction

details and technical data given here are not binding upon us.

Floor Boring Machine is ideal for force cutting and rough machining. It is competent in boring big surface and case parts. These machines are remarkably versatile as they can be outfitted with a various optional accessories and precisely tailored for any specific customer need.

|

|

| Technical Data of Floor Boring Machine |

| Particulars |

MM |

MM |

MM |

MM |

MM |

MM |

MM |

| Alloy Steel Work Spindle Hardened & Ground Diameter |

80 |

100 |

110 |

125 |

130 |

150 |

180 |

| Morse Taper Number |

4 |

5 |

5 |

6 |

6 |

6 |

7 |

| Max. Longitudinal Movements of Working Spindle |

500 |

510 |

510 |

600 |

600 |

650 |

750 |

| Number of Spindle Speeds |

9 |

9 |

9 |

9 |

9 |

9 |

9 |

| Range of Spindle Speeds - R.P.M |

15 - 250 |

15 - 250 |

15 - 250 |

15 - 250 |

15 - 250 |

15 - 250 |

15 - 250 |

| Longitudinal Work Spindle Feed No's |

9 |

9 |

9 |

9 |

9 |

9 |

9 |

| Vertical Headstock Travel Feeds (Including One Rapid) |

4 |

4 |

4 |

4 |

4 |

4 |

4 |

| Max. Height of the Spindle Axis |

1000 to 3000 mm |

| Longitudinal Traverse |

2000 to 12000 mm |

|

|

|